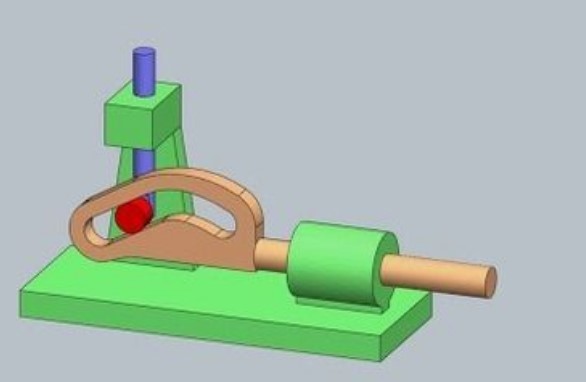

A cam and follower mechanism is a higher pair links device used in mechanical engineering. Roller or needle bearings, like the cam and follower, are manufactured to fit together precisely. They are available in various forms, each optimized for a certain set of tasks and results. Learn about the cam and follower’s purpose, range of uses, construction, parts, diagram, varieties, and operation. Remember that the process may also be understood in terms of a cam-follower.

Cam

A cam comprises a rotating component that imparts rotary or oscillatory motion to a machine component, called a “follower,” by physical contact. A cam is any mechanical element directly contacting a follower to transfer motion.

These systems allow one portion to undergo a rotating motion while another section experiences a linear motion. This allows it to act as a revolving wheel, electric steering wheel, or shaft, striking the different points of a lever along its circular course. In a steam hammer, a cam may serve as a tooth to produce concentrated bursts of force.

Follower

A follower is a portion of a machine that rotates or oscillates in response to the motion of a cam by direct contact between the two. When a cam is moved in a reciprocating motion, the followers move perpendicular to the axis of the cam. The follower will move along when the machine’s cam is in motion, either oscillating or reciprocating.

Mechanical Cams Have Several Benefits

Because of their capacity to generate motion, cams find use in various mechanical systems. Their many benefits and advantages over other techniques justify their widespread usage.

Accuracy Is Within Reach

A great degree of accuracy is possible using a superior cam mechanism. That’s why you’ll find cams in places like engines and clocks, where accuracy and precision are paramount.

They Are Able To Make The Motions Of Many Kinds

Because of its versatility, cam & follower mechanisms are widely used in mechanical systems. Linear motion may be generated using them, and rotational motion can be transformed into oscillatory motion and vice versa. This may be readily integrated into mechanical systems that use a broad spectrum of motion.

Challenges Associated with Cam Followers

- The conflict between the cam and their follower.

- When the machine fails, it should be turned off to limit the amount of damage.

- Higher production costs and more precision machining requirements.

- It is impossible to have a negative radius of curvature.

Conclusion

Because of their many advantages, cam and follower systems are still widely utilized today. There are some faults and limitations, but the benefits far exceed them. Cams have evolved into increasingly sophisticated designs that withstand significant wear over extended periods. Cams will continue to play an important role in mechanical systems for the near future.

Due to the considerable fluctuation in film thickness caused by changes in load, speed, or radius of curvature, a Cam And Follower Mechanism often functions in critical circumstances. Perfect or imperfect contact may restrict lubrication, increasing friction and wear. The contact for the cam follower is difficult to investigate in detail, making the pilot research not only required but also challenging.