Examining the Most Common Ways that Crystal Oscillators Can Malfunction

Crystal oscillators are used for a wide variety of applications. They fall under the category of fixed-frequency oscillators and deliver a stability and accuracy that most components can’t match.

Some of the other benefits of using crystal oscillators include:

- They are available in a range of frequencies

- They have a high quality factor (Q-factor)

- They have low phase noise

- They provide superior frequency and temperature stability

- They are inexpensive and economical

Because crystal oscillators are so stable and accurate, they are often used for applications that have a time-keeping element. You’ll find them in such things as microprocessors, computers, quartz watches, automobile features, communications systems, measuring instruments, medical devices, and GPS systems.

When crystal oscillators in these products and applications run optimally, everything functions as expected. However, if the product or application contains an oscillator that is damaged, has degraded, or is otherwise compromised, functionality of the application will be negatively affected.

Getting to Know the Signs of a Bad Crystal Oscillator

Crystal oscillators can be compromised or fail due to numerous reasons. They can be incorrectly installed, or the wrong type of crystal oscillator is being used. Crystal oscillators can also fail due to external reasons such as damage, the malfunction of an adjacent component, or an operating environment that’s too hot or too cold.

The following covers the many sources of crystal oscillator failure and their results:

#1 – Overdriving the Crystal

Crystal oscillators have a maximum drive level. When that level is exceeded, it is what’s referred to as “overdriving the crystal.” A few things can happen when a crystal is overdriven, which include:

- Reducing the overall lifespan of the crystal

- Unwanted spurs or harmonics

- Accelerated aging

#2 – The Circuit Board Is Overheating

Circuit boards can overheat for numerous reasons. Inefficient heat management, misplaced components, poor design, and using the wrong parts and/or materials can all play a factor.

Whatever the case may be, an overheating circuit board can compromise the efficacy of the crystal oscillator. In some cases, the malfunction may be intermittent. In other cases, the crystal oscillator will become permanently unstable.

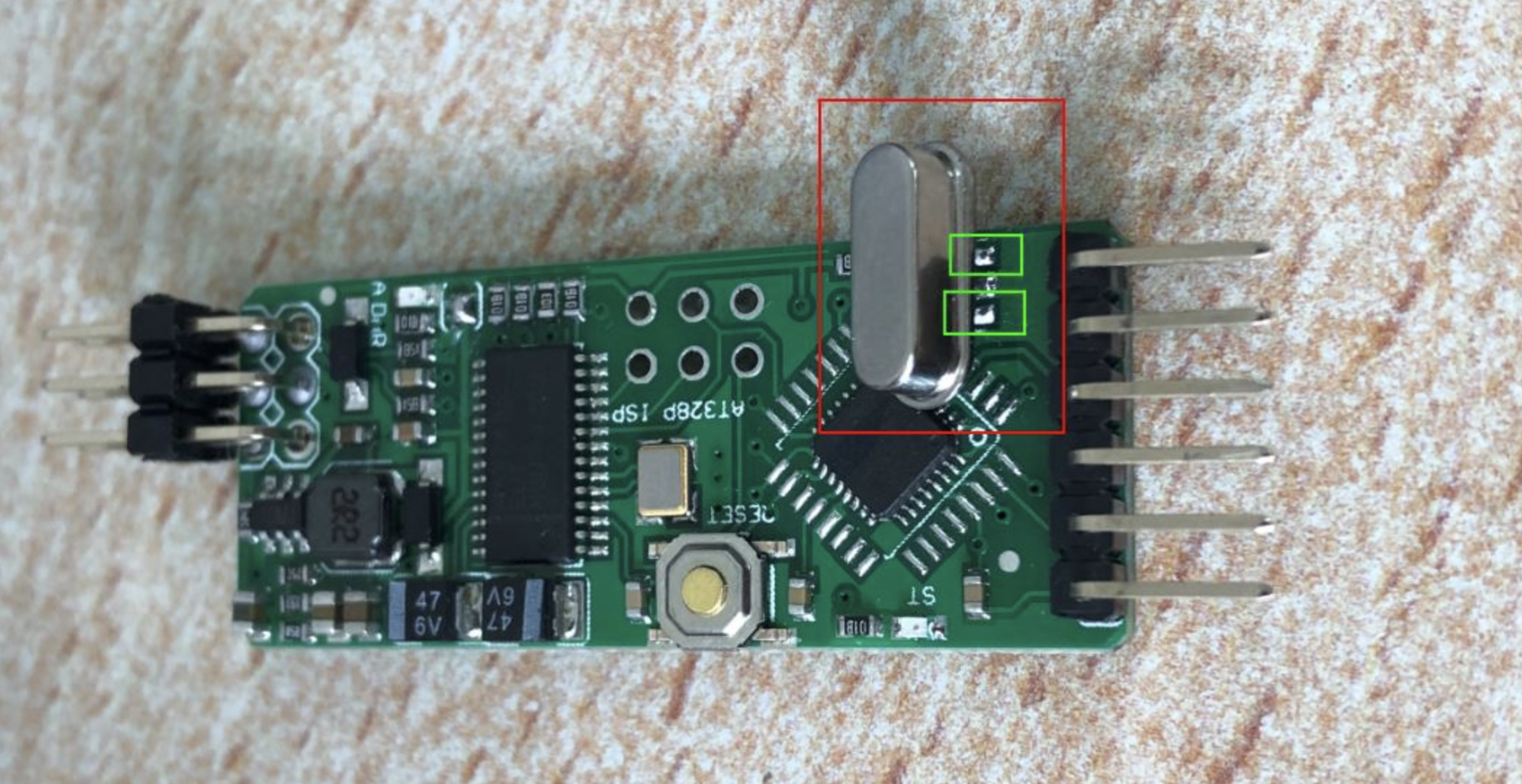

#3 – The Crystal Itself Is Damaged

If the crystal of the oscillator is compromised in some way, that can lead to a wide array of issues. They include:

- On-screen display fails to show or will show at random

- The motherboard of application does not respond

- Stable clock signal fails

- Frequency drift

- Waveform has become abnormal

- Vibration has stopped

Once it’s been determined that the crystal oscillator is damaged or compromised, it must be replaced by a functional one for your application to work properly.

#4 – Process Defects

Unfortunately, if one part or component of a circuit board is compromised, the effects tend to hinder the functionality of the entire application. Some of the most common examples of process defects include:

- Crystal process defects

- Module packaging process defects

- Chip process defects

Because defects can occur in numerous parts of the circuit board, the best thing to do is to run a full failure analysis to identify which specific component or part is defective.

#5 – Crystal Aging

When applied to quartz crystals, the word “aging” indicates that the frequency of the crystal has changed over time. Depending on the situation and variables, this can cause the frequency to either increase or decrease, resulting in frequency drift. Crystal aging is usually the result of adverse operating temperatures, excessive levels of vibration, and shock exposure.

The best method to mitigate the chances of crystal aging is to select a high-quality crystal oscillator that was manufactured in an ultra-clean facility; most reputable manufacturers are willing to share details about how their products are made. Additionally, products should come in hermetically-seal packaging to avoid becoming contaminated.

Finding Reliable, High-Quality Crystal Oscillators for Your Application

When it comes to crystal oscillators, you’ll find that there are an overwhelming number of options. The world of passive components is highly competitive, so sifting through all the companies that manufacture crystal oscillators to find the best one can be a time-consuming affair.

Our advice is to ignore price and focus on the reputation of the company and product quality. When shopping for components online, you’ll want to identify the companies that are an authority in their field and carry the components that meet your application’s specifications. Otherwise, you’ll purchase cheap components over and over again, when one quality one would have gotten the job done in the first place – and for the same or lower price.

Keep in mind, you can speak with a sales representative to walk you through the particulars of each product. You also can request crystal oscillator samples to confirm that they will work for your specific application or product. This enables you to “try before you buy” and establish proof of concept to your superiors and other engineers involved with the project.

The best ways to mitigate crystal oscillator issues is through research, testing, and verifying the component will work before placing a bulk order.